GBR GEN 3

The Most Versatile Fixtureless PCB Routing Solution

GBR GEN 3

The Most Versatile Fixtureless PCB Routing Solution

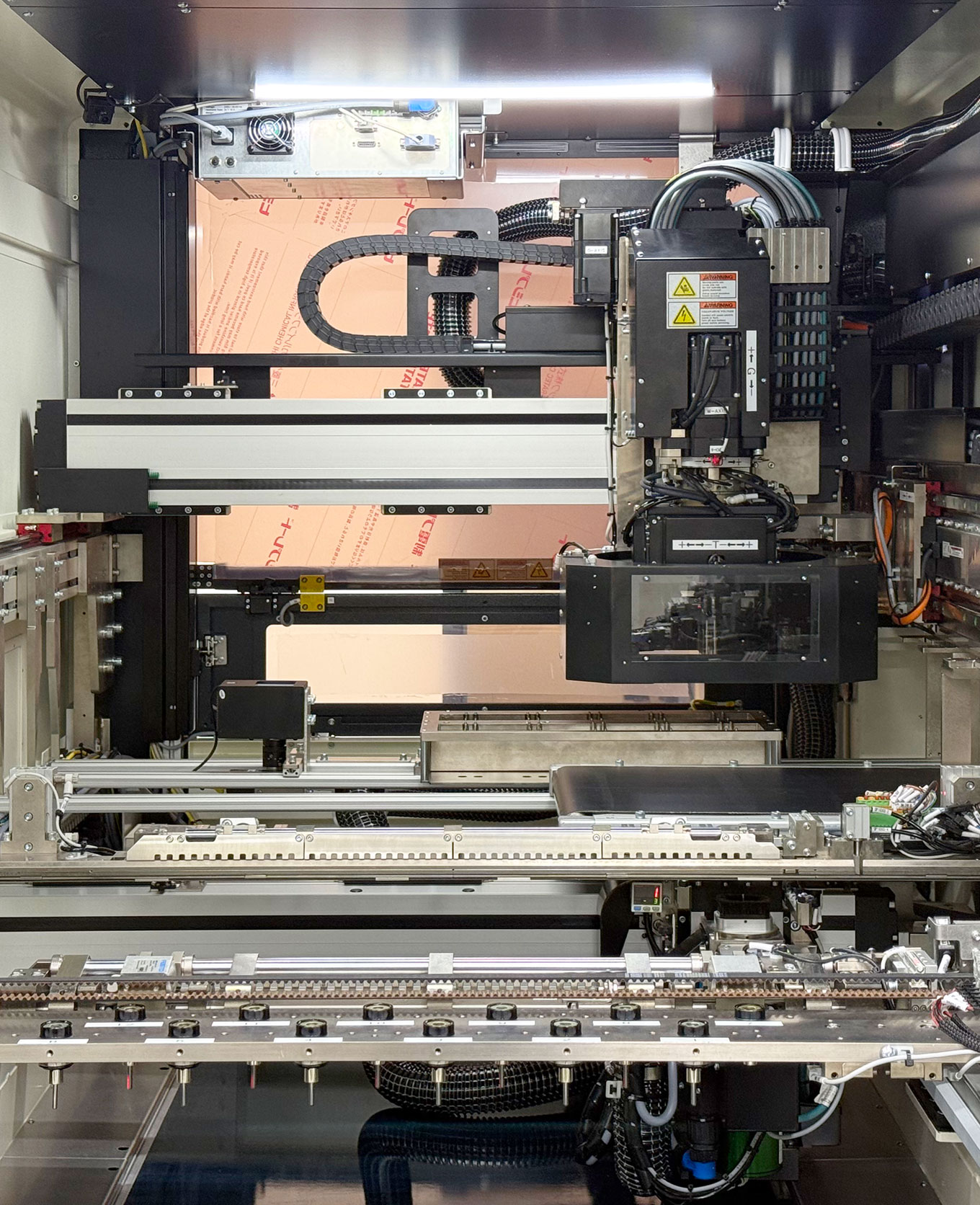

The GBR GEN 3 is an in-line PCB depaneling system engineered to process PCBA panels up to 600 mm × 480 mm with precision and efficiency.

Panels are fed into the system via a conveyor, where they undergo barcode verification, fiducial alignment, and secure clamping. A top-mounted robot and servo-driven gripper hold each PCB while routing is performed from beneath the panel, ensuring clean and accurate cuts.

Routed PCBs are then transferred to the offload station via high-speed linear axis, with options including flat belts, bridge axes, tray/pallet conveyors, or custom configurations.

Programming is fast and intuitive using a high-resolution camera and Windows-based software, with support for unlimited routing programs, making the GBR ideal for high-mix production environments.