APIL

Auto Printing Label, Inspection And Labelling

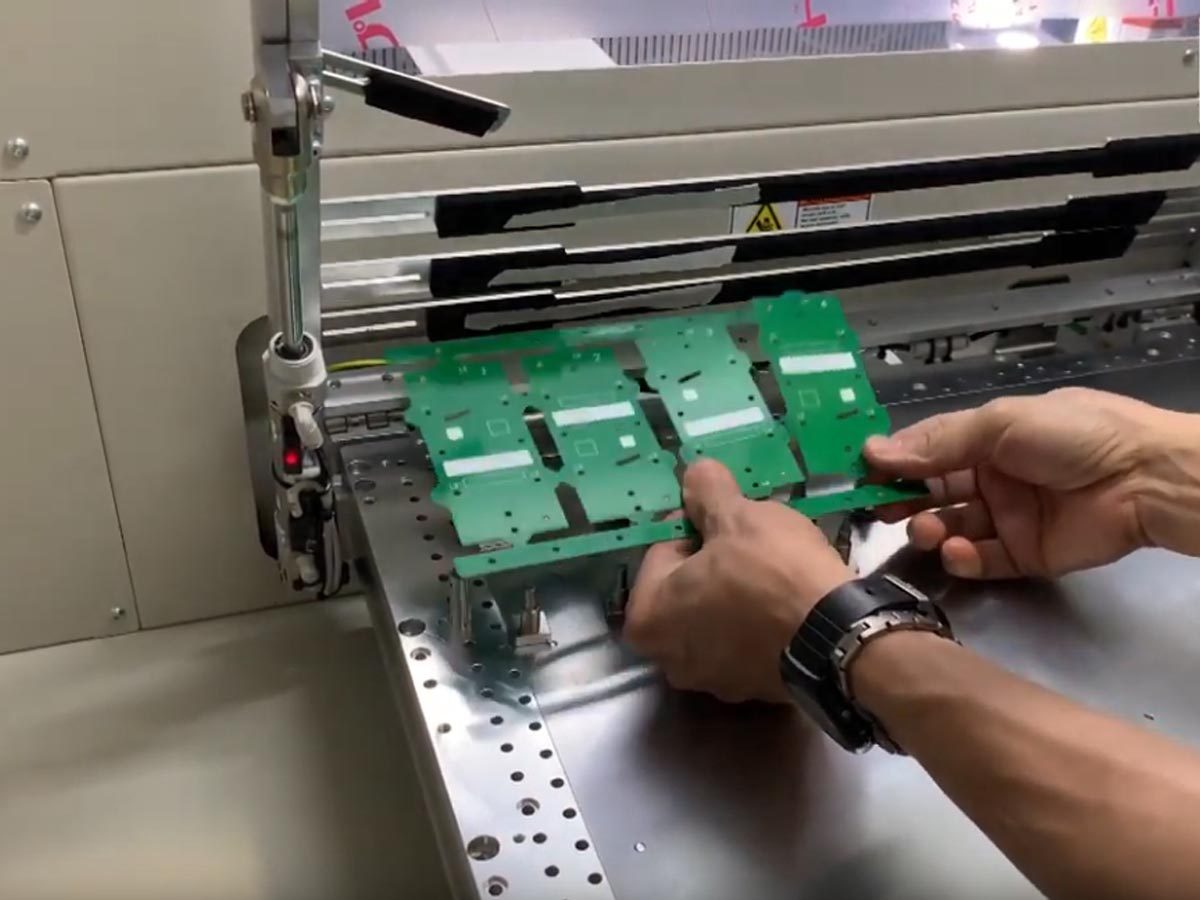

- APIL: Auto Labelling PCBA Inspect for Print Defects Including OCR Decode Inspect for Placement Accuracy Two Printers to Support 2 Labels per Product Inline System Using SMEMA On-Demand Print and Pre-Printed Label Support SECS/GEM Interface to Testers SEMI S2, S8 & F47 Compliance ESD Compliance User Friendly Software

- 320 x 250: L x W

- Scara Robot: : Dual tip : Quick change label heads : Label reject station for placing reject labels

- 3 stage conveyor: : Inline system : SMEMA communication to up / down stream systems : Panel barcode scanner for traceability : Process conveyor clamping to align PCBA panel

- Cycle Time: : 2.8 sec / label with 12up panel

- +/- 0.7 mm: : Cpk > 1.67

- 2 Printers: : ZT610 printers. : BarTender for Label design and printing : Support on demand and pre-printed labels : Label shuttle axis for label transfer from Printer to Scara Robot

- Conversion Time: : 15 min. : Conversion required when form factor

- 3 vision system: : PC based vision system : Label Inspection: Keep Out Zone check, OCR decode, Barcode decode, and Print quality grading : Post Labelling Inspection: Check for placement accuracy. Barcode decoding for traceability

- Panel ID: : Panel is traced using Panel ID 2D barcode

- SEMI: : SECS/GEM compliance : SEMI S2/S8 compliance

- ESD: : SEM F47 compliance : ESD compliance

- Machine Size (L x W x H): : 1553 x 1653 x 1802

- Power: : 1P + N + E, 230VAC, Full Load Current: 6A : CDA: 6bar